On Wednesday we left for San Francisco. Leg one was from San Diego to Ventura, which took 24 hours. We left at 1130. For the first seven hours, the wind was steady at 15 knots from the forward port side, with two to four foot swells, gently shaped, at about 3 – 6 second intervals. Wind chop was about 1 – 2 feet, also gently shaped. We wish all rides in head seas could be so nice! Speeds varied from 5.5 to 6.5 knots at 1775 RPM depending on currents.

As the sun started to get lower in the sky, the wind picked up to 18 – 20 knots and the wind waves became slightly bigger at 2 – 4 feet, but noticeably sharper and at more rapid intervals. The pointier waves caused Kosmos to hobbyhorse and sent some sea spray over the bow, but it still was not a bad ride considering it was head seas.

The rougher conditions only lasted a little over an hour, then we got into the shadow of Catalina Island, where the seas slowly but steadily improved. By midnight the ride was relatively pleasant again (for head seas) and speeds had picked up to 7 knots. There was no moon and it was pitch black out, so there was no visibility all night.

We expected conditions to worsen once we passed Catalina, but they didn’t. In fact, they continued to slowly and steadily improve the whole rest of the trip. By 1000, the wind chop was completely gone, leaving only the gentle swell, making for a lovely ride.

Shortly after leaving San Diego, we had a small SNAFU arise. The entire downstairs reeked like the blackwater tank. Christi guessed the duck valve in the forward toilet did not have a good seal and was letting the tank odor up. Our forward stateroom has two dorade vents, and while we were in Tahiti, Eric cleverly installed a fan in front of one of the vents to push fresh air into the not as well ventilated master stateroom. The reason the smell was so strong in the entire downstairs was because the smelly air was being blown around down there.

To ease the underlying problem, we emptied the tank as soon as we were far enough out to sea. We then partially filled the blackwater tank with fresh, hot water (from the shower) and emptied. We put in another round of fresh water and added a product called Kills Odors that claims to neutralize the blackwater smell. We are letting the water and chemical slosh around in the blackwater tank in the hopes that the smell of all the residual stuff in there is neutralized. To stop the smell altogether, we simply switched the toilet to go overboard, so if any air got in, it would be fresh air, not stinky tank air.

Eric was not as convinced as Christi that the duck valve was the problem. He was worried the smell may have been from something stuck in the lines, so we also flushed into the lines a cleaning product called Clean Potty that claims to dissolve solids and crossed our fingers it would dissolve anything hiding in there. He also said it was possible the smell was coming from the gray water tank and covered the forward shower drain to block any smell from coming up. After a couple hours, the smell went away.

It is ironic that we have a toilet problem again so soon after the last one. Only three weeks ago, the master stateroom toilet started periodically flush itself. Over the phone, a marine plumbing company deduced the control panel went bad. The control panel had to be special ordered, which took a week. Then the repair guy was swamped and couldn’t come out for another week. But the repair guy was worth the wait. Changing the panel out was easy and took no time at all. Eric probably could have done it himself, but he didn’t want to.

We say the repair guy was worth the wait because he was honest, straight forward and on time. Over the last year or so, we have had some headaches with different repair people, so we especially appreciated this gentleman. With Eric so busy working, he has had to rely on other people to work on the boat.

About three months ago we anchored out overnight and noticed the windlass wasn’t working quite right. Three weeks ago, we noticed it was dead. The repair guy we called made an appointment for a week later, then called last minute to reschedule. He stood us up altogether for the second appointment. To make it up to us for standing us up, he came out on a Sunday. We thought he was coming to do the work. Upon arrival, he said he was only doing an estimate. He asked Eric a lot of questions to gauge just how well Eric understood the systems onboard and how much money Eric made, which made us uncomfortable. The repair man diagnosed the problem as the motor and told Eric it would take eight hours to swap out. And he’d have to charge us a rush fee to squeeze us in before we left for San Francisco.

After he left, Eric pulled out the spare motor we had onboard and thought it looked easy enough to change, so he changed it himself in ½ hour. The windlass was still dead. He emailed the man to let him know it wasn’t the motor. The repair man got angry, and emailed back that he didn’t want to do the job because he couldn’t get away with padding the bill (we are paraphrasing. His actual words weren’t nearly as professional, including phrases like “cheap rich bastard”). Eric diagnosed the problem as the solenoid. Fortunately, the part was readily available and Eric installed it in an hour. And the windlass now works like a charm!

In March we took the boat into a local boatyard to rebuild the alternator (it was working fine but at the end of its expected life) and change the motor mounts out (the engine was vibrating a little because the mounts, which are essentially shock absorbers, were starting to go). When the alternator was put back on, Eric looked at it and said “That isn’t our alternator.” A fight ensued where they adamantly insisted it was indeed our alternator. The fact that it was a different color, had a different brand name, was made in a different country, and had a different amp rating than ours didn’t matter. They swore up and down it was ours. We got management involved, who said, “Well, no it isn’t yours. Yours wasn’t worth fixing so we put in a brand new one. What do you care?” and insisted all alternators were the same and we should be grateful to have a new one. After much fighting, we got them to agree to install a new Leece-Neville (the same brand as the original alternator).

Christi was onboard the entire time the boat was in the yard, working quietly on book 2 in the pilot house while the mechanics worked in the engine room, entering via the hatch in the salon. She kept track of the hours. Total hours for all people was 11.5 hours, including removing and re-installing the alternator. They billed for 24.5 hours of labor (at $80 an hour!). They insisted we had no idea how many labor hours were worked since we weren’t onboard. After much arguing, we compromised at 16, but we still feel like we were ripped off on labor.

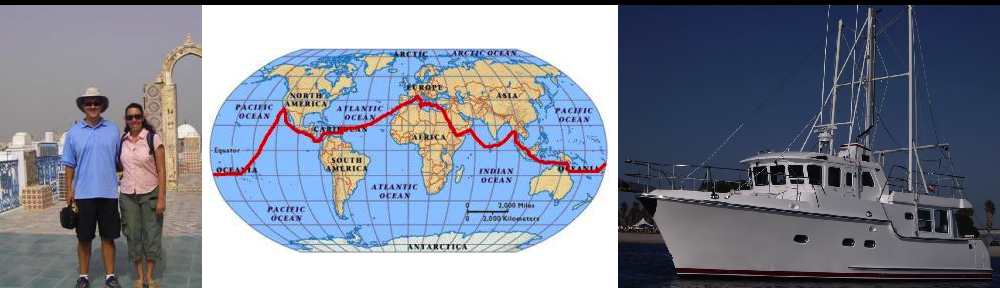

Another major repair we had done was to the stabilizers. A few months after we returned from our circumnavigation, we wrote a post about changing our starter battery. The starting battery was dead and Eric was paralleling the house bank to start the engine. Our stabilizers coincidentally went dead about the same time. We were dreading the stabilizer repair. But much to our surprise, when we changed the starter battery, the stabilizers magically worked again. They had been running off the starter battery the whole time, not the house bank as we had assumed!

Anyway, since then, we noticed the stabilizers were making an unusual tapping noise. Eric thought it was the pump. We took Kosmos to Dana Point and had PAE work on it. They said it wasn’t the pump and changed out some other parts, but it didn’t stop the tapping. We had a local San Diego mechanic who was TRAC certified come out to work on it multiple times over a six month period. At first they argued with us that there was no unusual noise and it was our imagination, which did not make Eric happy. That stabilizer is next to our bed, inches from Eric’s head, and the noise kept him from sleeping when the stabilizers were on.

They also insisted it couldn’t possibly be the pump, but were never able to diagnose the problem. They changed out just about everything while playing the process of elimination game–except the pump, which they still maintained could not be the problem. We finally complained to ABT, who flew out their top guy from Seattle to diagnose the problem. It was the pump. Over the six months the local guys worked on the stabilizers, they rescheduled us at the last minute twice and stood us up altogether three times.

Even though we weren’t thrilled with the local certified ABT guys, we still love ABT overall. They didn’t charge a penny for the Seattle guru to come out (though we did pay an arm and a leg to the local guys for all the work). They gave us a free upgrade on our control panel display, which is easier to read than the old one. And, on the bright side, our stabilizers are now essentially brand new.

While we are complaining, we want to add one more. Last November we had a certified Lugger mechanic change the oils, filters and so forth. The transmission filter recommended by ZF costs $150, so instead of asking, he assumed we wanted a $27 filter that was the same size. We never noticed the difference.

A few weeks later, “Lugger” Bob Senter (the renowned expert on Luggers/Northern Lights) came to visit us. Bob immediately noticed the wrong filter and explained it wasn’t rated at a high enough pressure for our transmission. Bob told us it was possible that our transmission filter would blow and recommended getting the right one installed ASAP. We called the man who did the work and told him we wanted him to install the correct filter. He told us the filters were identical. When Christi insisted they weren’t, the man said “What dumb yahoo told you such nonsense?” When Christi said “Bob Senter,” the man simply said “Oh.”

We’ve done more work, too, but since this post has gotten long, we’ll stop here.

This is part 1 of an 11 part series on our time in San Francisco. Read part 2 here.

Finally, back out on the sea! Great update.

Great to see you writing again. Can’t wait for the second book.