Here are the dates:

- Factory shipped (on this ship): Jan 31, 2006

- Arrives Dana Point for commissioning: Feb 25, 2006

- Boat done: Around May 2006

Here are some pictures from the factory:

And here are some from a bit later:

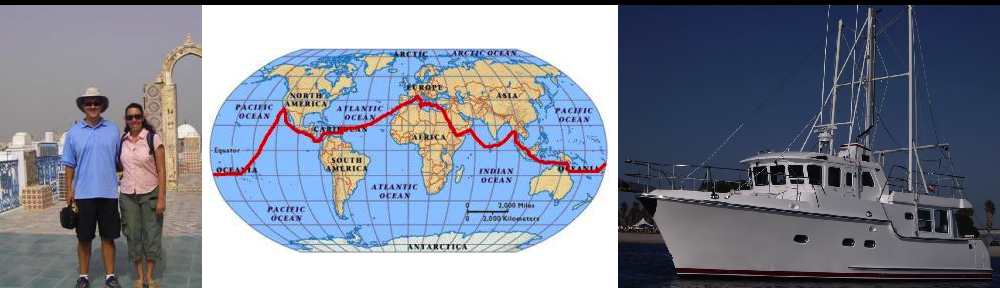

Our Nordhavn 43 is a production boat, which means the fiberglass hull is formed from a re-usable mold. The hulls on all the model 43 boats are exact copies. However there are many options with a Nordhavn and no two are exactly the same when they are completed. As hulls are built the are referred to by their hull number. So before she becomes Kosmos, our boat is hull number 18 of the Nordhavn 43 foot model powerboat, or simply 43-18.

The boat yard factory is in Taiwan. Once completed it is put on a cargo ship and sent over to Dana Point California, which takes about 3 weeks. In Dana Point the boat needs to be commissioned. This is a lengthy process. During commissioning they check out all the numerous boat systems and put on final equipment. For example some equipment installed in Dana Point will be the pilot chair, paravane stabilization, the mast and smokestack, and various electronic pieces. Even a custom manual is created for the boat during this time. A proper commissioning process is one of the reasons we really trust our Nordhavn.

The factory construction time is about 6 months. Add in commissioning time and it takes about 9 months to make the boat.

If you look carefully in the later pictures you can see a couple interesting things. One is the cabinets instead of the settee in the salon. You can see a radio sitting on top of the cabinet. This is the port aft part of the salon. We think this is very functional space, both on top of the cabinet and inside. You cannot see it, but the cabinets go much deeper than the wall, because just below the window the hull flares out for a side walk way.

Next is on the interior of the pilot house you can see where we had a cubby hole for the wing engine control levers. We got levers instead of the standard push pull handles since we have heard the push pull can be difficult to use and often slip from their settings. To see it look at the raised steering wheel block, then look to port and down. We thought this was nice out of the way place, yet still accessible and functional for when we use the wing engine. Hopefully we will never have to use the wing system for propulsion, but if we do we know we can rely on the controls.

Looks great! Gotta see the captain’s chair. 😉